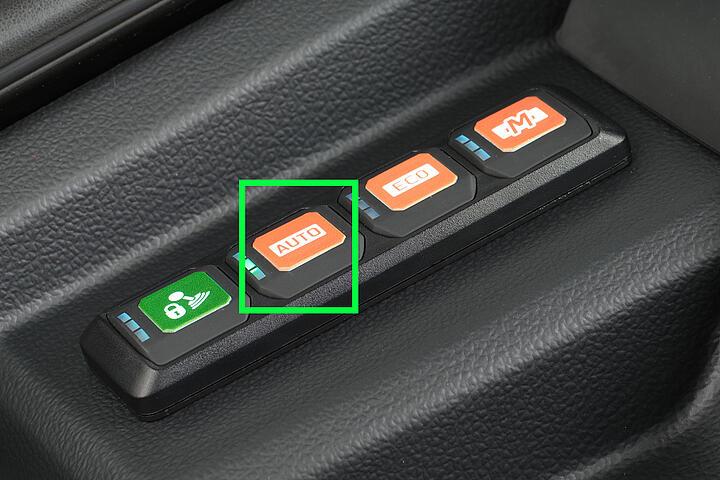

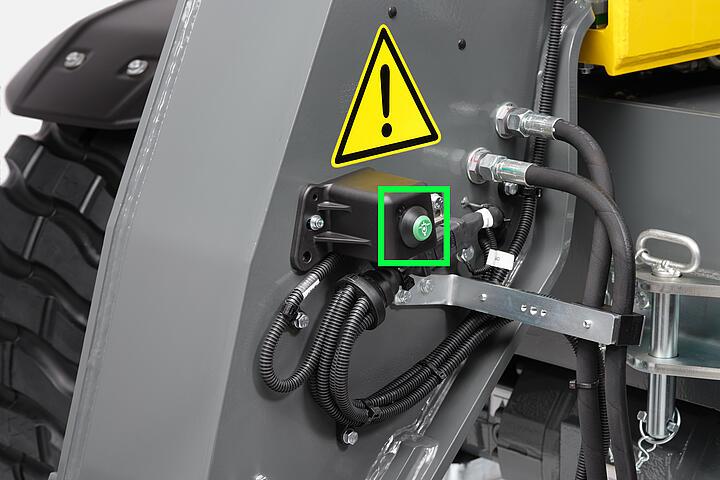

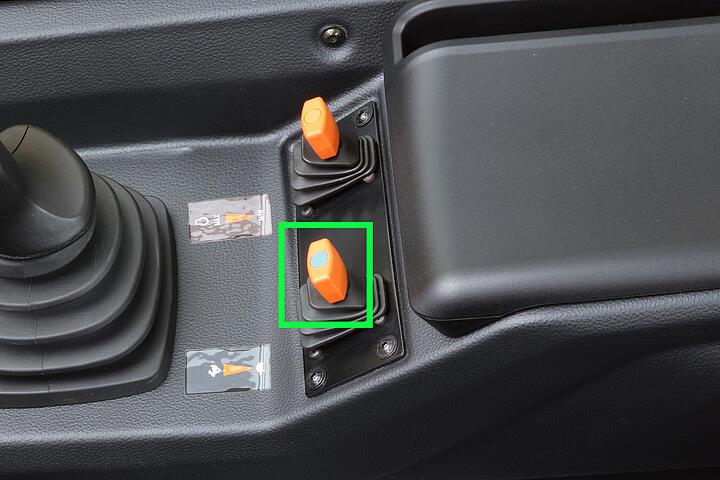

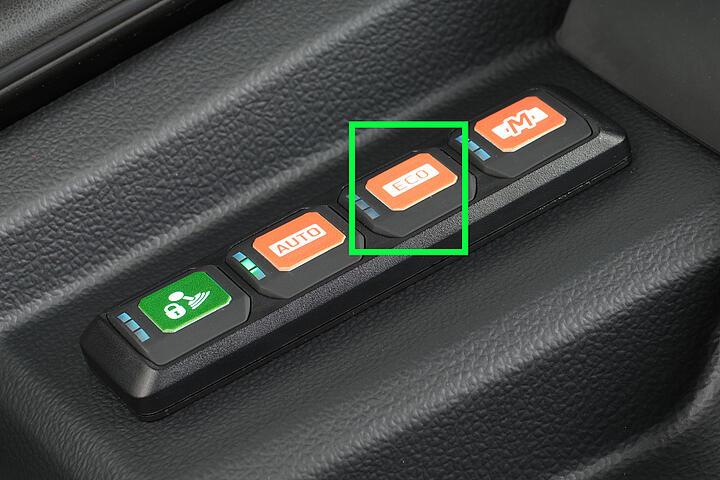

The TH625 is the compact power pack with a lifting height of 6 m and a payload of 2,5 t. The following features characterize the TH625 telehandler: Comfortable cab with excellent ergonomics and all-round visibility, electronically controlled travel drive with various travel modes, robust telescopic arm with excellent view of the attachment, wide range of options and a modern machine design. The transversely installed motor and the optimized arrangement of components ensure very good maintenance accessibility. The integrated driver assistance system VLS (Vertical Lift System) ensures safety and also increases operating comfort. The TH625 combines power, reliable hydraulics and compact dimensions with sophisticated technology and a convincing price-performance ratio.